18550502088

2021-07-23

Plastic parts are mainly used in automotive interiors and are widely used in the automotive industry. However, the current automotive interior parts on the market are mainly inspected by humans. Few companies adopt automated visual inspection machines. On the one hand, it is due to cost issues. , On the one hand, due to the detection problem, even the use of automated detection can not be fully detected.

At present, there are mainly the following problems in the detection of plastic parts of automobile interior parts:

1. Car interior parts troublesome plastic products, plastic product testing generally detects parting surface burrs, surface defects, pits, pits, etc., as far as parting surface burrs are concerned, if the backlight is used, it can be projected. It can be detected, but in fact most of the burrs cannot be projected, so it is difficult to sort by high-speed detection.

In addition, automotive interior parts are mostly black. From the perspective of lighting, black absorbs light, so that the pits and pits on the surface are not easy to be photographed by the camera, which will also affect the detection; in addition, the surface of the plastic parts is generally lacking. The location is still uncertain, which adds to the difficulty of detection.

2. As far as visual inspection is concerned, image inspection is more suitable for plane inspection. Half of the interior parts are three-dimensional and multi-faceted. It is difficult for the camera to detect all sides of the product, which is also one of the inspection difficulties.

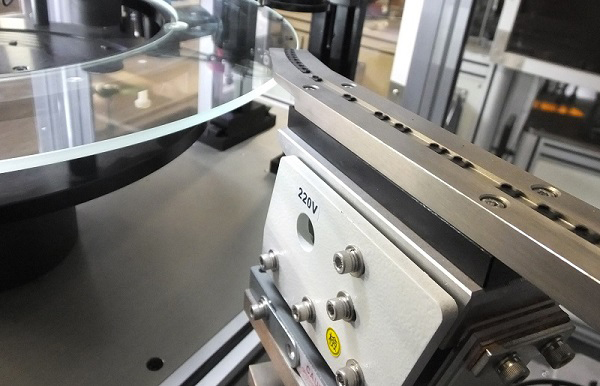

All in all, as far as the current optical inspection machine market is concerned, the inspection of plastic parts in automotive interior parts is difficult to achieve high-speed full inspection, which severely restricts the development of the interior parts industry, and at the same time plastic parts defect detection also gives us Bringing new industry opportunities, Suzhou Zhuo Jin Communication Co., Ltd. is fully committed to the development and production of machine vision automated optical inspection equipment. We will continue to provide customers in various industries with new system solutions

H

I

D

E