18550502088

2021-07-23

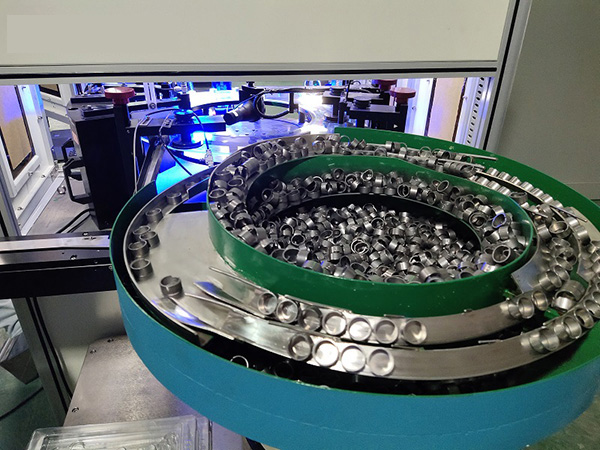

Fast and orderly automatic feeding is an important performance standard for optical inspection machines. If an optical inspection machine cannot load quickly, how can high-speed automatic inspection be achieved? Vibrating plate feeding is a commonly used method of feeding. Next, we will talk about an important part of the optical inspection machine-the vibrating plate feeding mechanism.

Friends who are familiar with the vibrating plate know that if the shape of the material workpiece to be detected by the optical inspection machine is quite different, it is not easy to load the material in a vibrating plate. If the size and shape of the material workpiece are single, the feeding is fast and easy to adjust, and the maintenance cost Low.

Many optical inspection machine users want to use a vibrating plate to meet the loading of various materials and workpieces. When each material is changed for a long time or the old material is stuck, they feel that the equipment is not easy to use. In fact, the more complex the equipment, the more difficult it is to operate. More and more maintenance, a vibrating plate can only detect one type of material, then this vibrating plate may not need to be adjusted when it is scrapped. On the contrary, if a vibrating plate is compatible with dozens of materials of different sizes, it may need to be frequently Adjusted, if the user factory of the optical inspection machine does not have strong hands-on operators, either train the workers to counter-offer first, or do not inspect so many materials first to avoid problems and do not know how to solve them. In many cases, an ordinary person may not be able to debug a complex vibration plate in a day, but a professional and experienced master may be able to handle it in a few minutes. Any machinery and equipment are not capable, especially similar foreign equipment has a relatively single detection function, so that high stability can be achieved.

H

I

D

E