18550502088

2021-07-23

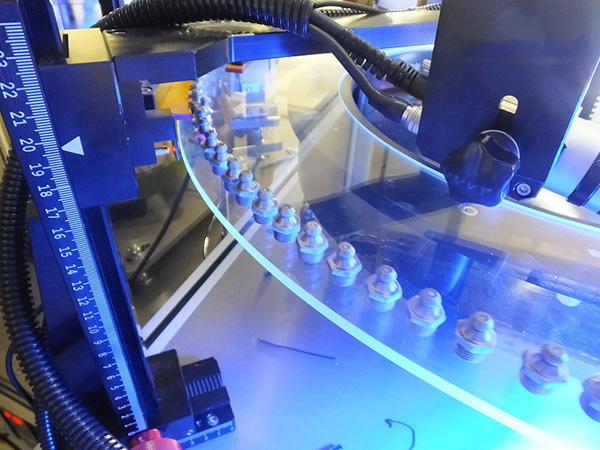

Screw testing machines are widely used. You can see screw testing machines in the automotive parts, mobile phone parts, hardware, electrical and electronic product manufacturing industries. The screw testing machine equipment company reminds users how to buy one Which screw inspection machine is suitable for you?

How to choose a screw testing machine?

Buying a satisfactory screw testing machine often needs to pay attention to some things. First, know which screws you need to test, including (specification and shape pictures, and speed requirements). These need to be provided to the screw testing machine manufacturer in advance, and then the screw testing machine is required. Manufacturer's quotation.

If the price is right, the equipment configuration function can also meet your actual screw screening needs, and you can go to the manufacturer to test the machine later, and there are related equipment prototypes for on-site testing to actually verify the equipment detection capability. Then, one step must confirm the delivery date of the equipment and negotiate the payment method.

The common testing items of the screw testing machine are: large diameter, small diameter, pitch, thread length, cross groove, flat groove, Y-shaped groove, broken needle plugging hole, etc., head crack, head diameter, head thickness, and some occasions with high requirements. Need to detect 360 thread trauma.

H

I

D

E